Bad infrastructure hurts business: RMG makers

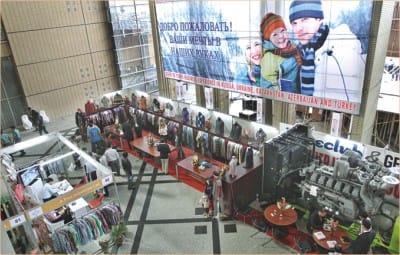

People visit stalls of a three-day annual exposition, BATEXPO, at Bangabandhu International Conference Centre in the capital yesterday. Bangladesh Garment Manufacturers and Exporters Association organised the event. Photo: Amran Hossain

Local garment makers and foreign buyers yesterday called for better infrastructure to help Bangladesh maintain its growth trajectory in the world apparel business.

They also said rules should be made easier to allow entrepreneurs to set up businesses easily.

Bangladesh's apparel exports are growing remarkably, but European and American buyers are trying hard to weather impacts of the global economic crisis.

Speaking to The Daily Star on the sidelines of BATEXPO 2011 at Bangabandhu International Conference Centre in Dhaka, industry people said the country could do even better.

Bangladesh Garment Manufacturers and Exporters Association has organised the 22nd Bangladesh Apparel and Textile Exposition where local and foreign companies are showcasing their products and services in 146 stalls.

The three-day annual fair ends tomorrow.

Abu Henry, chairman of Novimoda Knitwear Ltd, an export-oriented garment company based in Gazipur, directly markets his products at international markets particularly in Italy that buys 80 percent of his items.

“We are growing despite the gloomy world economic scenario. The order flow is encouraging," he said.

He said the government should do more to stop buyers from switching to other markets. "We have technology and money, still the buyers go away. We need to sort out the energy crisis and make the licensing process easy to keep them."

"We don't want any financial support from the government. We need to improve the road network fast. Particularly, the traffic jam saps the buyers' interest of doing business here. Many of my Italian friends have pointed to the problem."

The cost of doing business has gone up due to the energy crisis, he said.

Sumon Ahmed, assistant marketing manager of Yester Accessories Company Bangladesh Ltd, a Bangladesh-China joint venture, said his company has enough orders at present. Yester produces tags, zippers, snaps, eyelets, belts, buckles and fasteners.

Ahmed said his company is also investing a lot to expand the capacity of the factory, as the demand for locally-produced accessories is rising as domestic manufacturers are able to offer products at prices lower than China.

Akther Uddin Nazrul, a marketing manager of Nassa-Taipei Textile Mills Ltd, however, said the order flow to the country's textile sector is slow now compared to that of the garment sector.

"We do not see expected diversion of orders from China in textile sector, as Chinese exporters can still sell at lower prices. Bangladeshi manufactures also prefer to source fabrics from China although we produce quality materials than the country."

Nazrul also said the textile sector is under pressure due to regular fluctuation in yarn prices. "Whenever our business peaked we saw gambling over yarn prices. As a result, the cost of doing business has gone up."

"We made good profits in 2010. We cannot say at this moment how the business will fare in 2012."

Jorge Andres Pallisso, president of Nicaragua-based Manga Apparel SA, an international wholesaler, said the quality of Bangladeshi products is getting better and the price is fair.

Bangladesh could do better if it can improve its transport network, he said. “I do not understand why there cannot be a better transport network between Dhaka and Chittagong."

"The labour condition is important to us. They should also stick to international standards," he said.

Pallisso, who has been doing business with Bangladeshi exporters for three years, thinks that the garment price should go up as it has been so low for years.

Takahiro Narai, an assistant marketing manager of Maruhisa Pacific Company Ltd, said his factory in Adamjee Export Processing Zone is looking for long-term business in Bangladesh.

"Now we are only exporting to Japan, but we have plans to send products in European markets. We are working in that line and making new investment," he said.

Narai said they are setting up dyeing and knitting units in the factory. "It is difficult to buy the items from outside the EPZ, as we have to supply finished products in the shortest possible time."

Mohammad Mostafa, assistant general manager for merchandising of Mahmud Group, a denim maker, said although the order flow is down now Bangladeshi exporters should not worry about the situation. "We are under pressure from three fronts -- the global economic crisis, the hike in gas and electricity prices in domestic markets and the buyers' pressure to cut prices."

"We are receiving less work orders due to the crisis. But we hope the situation will not last long. So, we are doing business at less profit."

"I think after China global suppliers have no option than Bangladesh. We also produce quality products."

The Group now produces 10,000 pieces of denim trousers a day. It will be increased to 30,000 pieces in January, said the official.

Faruk Ahmed, a senior merchandiser of Asrotex Group, said Bangladesh can produce high-end products to enter new markets.

He said the government should release the 10 percent incentive to help the exporters stave off impacts of the global crisis.

Ruhul Amin, assistant marketing and merchandising manager of Montrims Ltd, an accessories supplier, said their buyers say that the prospect is good in the coming days. "We are also investing heavily to expand our capacity."

Kazi Md Uzzal Hossain, a senior executive of KDS Group, an export-oriented business producing garment accessories such as hangars, buttons, sewing thread, labels and tags, said his company is also investing to expand the capacity.

Gian Galeazzo Boschetti, a co-owner of Europoint, a buying house in Bangladesh, said Bangladesh is being very competitive in terms of prices and the average quality of its products has improved in the last few years.

Boschetti said a number of clients who had moved to China are now coming to Bangladesh. "Bangladesh is also doing a fantastic job, but it can do much better. The country needs a lot of infrastructure. If you do not have proper infrastructure you will have no business."

"If buyers have to sit down three to four hours in cars for a one-hour drive then they will not come back. There are a lot of things that can be improved,” Boschetti said.

"In general, the orders are going down and the scenario is a bit worrying."

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments