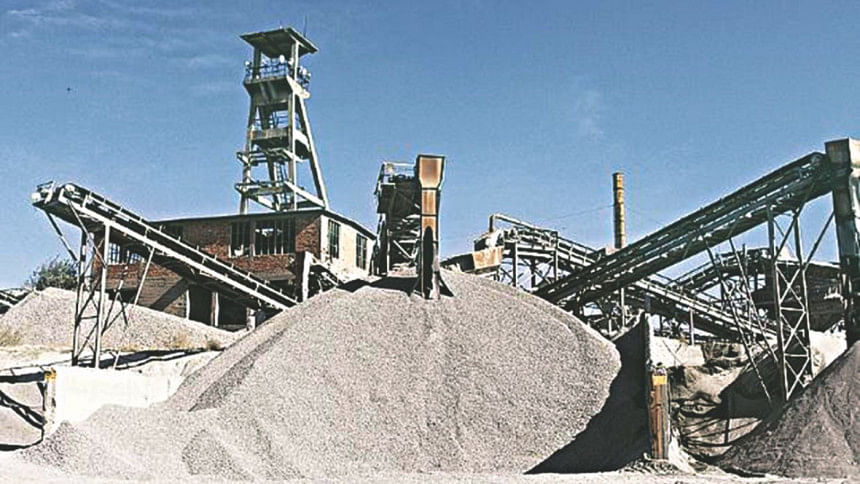

Cement industry posts record sales in 2018 amid challenges

Despite various internal and external challenges, cement manufacturers posted the highest ever single-year sales in 2018, on the back of rising consumption of the key construction material in rural areas and development projects, said industry people.

"2018 was definitely a good year for us. There is no doubt," said Md Shahidullah, vice president of the Bangladesh Cement Manufacturers Association (BCMA).

He said cement sales stood at about 33 million tonnes in the year, the highest on record, much ahead of about 30 million tonnes seen in recent years.

Consumption grew 12 percent in 2018, way ahead of 8 percent to 10 percent average annual growth recorded in the last decade, said Shahidullah, also the managing director of Metrocem Cement Ltd, a manufacturer and exporter.

He credited the increasing demand from individual homebuilders, mega projects, and rebounding real estate for the growth.

The growth in the industry came despite various internal and external challenges.

All the big cement grinders have been adding capacity in the past two years and this is still continuing, leading to an excess grinding capacity compared to demand which is seeing downward pressure on prices, said Masud Khan, chief executive officer of Crown Cement Group, another manufacturer and exporter.

He said raw material prices increased in 2018 sharply compared to the previous year. Clinker price skyrocketed due to the scarcity of supply from Vietnam, Bangladesh's major source of the raw material needed to produce cement.

Freight costs went up sharply due to the increase in fuel cost, among other reasons. Transport cost has also seen a sharp increase due to the weight restriction imposed by the government on highways, according to Masud.

The cost increase has been exacerbated by the major devaluation of the taka against the US dollar. The taka devalued from Tk 80 per USD to Tk 85 per USD, an increase of 6.25 percent.

"This has severely dented our margins since all cement raw materials are imported," said Masud, whose company delivered a sterling top line growth of 33 percent in revenue in 2018.

He said all cement players had their backs to the wall and finally in March 2018, all the players went for a price increase after six years of no price increase.

"However, this increase had only a brief respite since the input costs have skyrocketed for various reasons."

The price of every raw material has gone up by USD 5 to USD 10 per tonne on average in the last one year. The local market, however, hasn't seen the same level of commercial adjustment, said Amirul Haque, managing director of Premier Cement.

"The growth in 2018 has not been bad. In fact, the current growth rate is sustainable."

He said this growth is being driven by the rural economy, which is developing and will develop further in the years to come.

"People are building homes using bricks instead of tins. Schools, colleges and other structures are being built across the country. The government's consumption has also seen substantial growth."

The demand for cement in Bangladesh is 31 million tonnes a year and the industry's existing 32 plants have a combined production capacity of 54 million tonnes, according to Manwar Hossain, senior vice president of the BCMA.

The entrepreneur said the industry faced a difficult year largely because of internal factors as cement manufacturers have increased production capacity without taking into account the real growth of the market.

"Overcapacity is a huge problem for the industry and because of it many companies found it difficult to make profit in 2018. Many companies might even have failed to make any profit at all."

"I think the current business trend will continue in the next two to three years as consumption will not double overnight. So mill owners have to increase efficiency and productivity in all areas."

Manwar, also the group managing director of Anwar Group, said one single truck can now carry 12 tonnes of goods, down from 25 tonnes previously because of the load restriction, which has increased the demand for vehicles and the carrying cost.

He said the government should make the river route smooth to redirect the movement of raw materials and finished products away from the roads. "Then we will perhaps get some breathing space."

The government should take steps to increase the number of barges, he said.

Manwar said Anwar Cement Ltd posted 50 percent sales growth in 2018 compared to the previous year.

Talking about challenges, Amirul Haque said the cement industry is a private sector-led business.

He expects the industry to experience the same level of growth in 2019 if there is a congenial atmosphere in the social, economic and political spheres of the country.

MI Cement, which produces Crown brand cement, still holds the first position when it comes to exports by delivering about 9,000 to 10,000 tonnes per month on average to the neighbouring Indian state of Tripura. The total value is in excess of USD 8 million. It controls more than 50 percent of cement exports.

Other than MI Cement, four to five other companies, including Metrocem Cement Ltd, also export construction raw materials.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments