Ceramics industry reeling from three-pronged assault

The ceramics industry has been desperately seeking respite from a spate of crises in recent months, but their woes have only deepened due to a worsening gas crisis.

One of the major problems facing the industry has been brought on by inflationary pressures, which have eaten away at local demand for ceramics. Annual inflation rose to a 12-year high of 9.73 percent in fiscal year (FY) 2023-24, the highest since 2011-12, according to the Bangladesh Bureau of Statistics.

According to industry insiders, this has caused sales of ceramic products to plunge by 15 to 20 percent over the past four to five months.

Furthermore, there has been no relief from international buyers. On the contrary, exports of ceramic products declined by around 25 percent, according to the latest data.

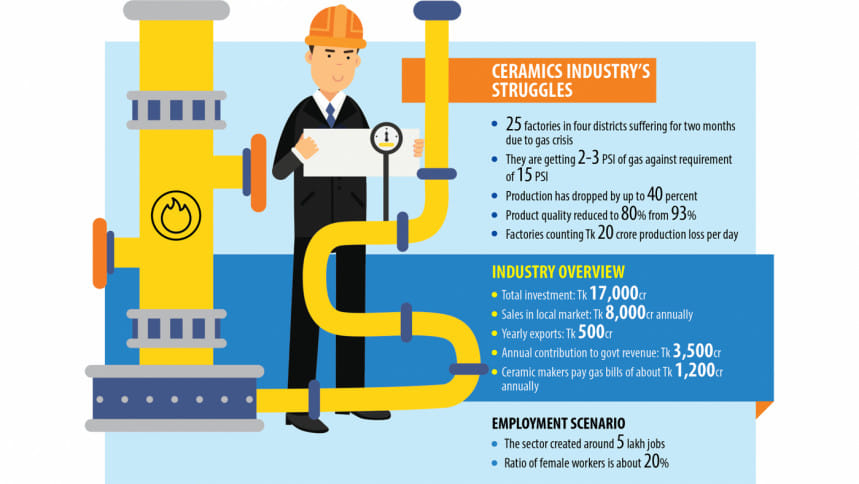

Further exacerbating the situation over the past two months is the fact that ceramic industries in four districts have been contending with massive productivity losses due to a gas crisis. Industry insiders said they were counting production losses amounting to Tk 20 crore per day.

Exports of ceramic products fell to $30 million during the July-May period of FY24 compared to $39.86 million the prior year, showed data from the Export Promotion Bureau.

Further exacerbating the situation over the past two months is the fact that ceramic industries in four districts have been contending with massive productivity losses due to a gas crisis.

Industry insiders said they were counting production losses amounting to Tk 20 crore per day.

"Around 25 ceramic factories, located in Dhaka, Gazipur, Mymensingh and Narsingdi, have been getting insufficient gas pressure for the past two months," said Md Mamunur Rashid, senior vice president of the Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA).

He said ceramics-makers normally require 15 pounds per square inch (PSI) of pressure to maintain product quality but they are getting only 7 to 8 PSI.

As a result, around 7 percent of products did not pass the quality inspection previously, but that number has ballooned to 20 percent due to the crisis, he said, adding: "Our profit declined by at least 25 percent due to production being hampered."

He also highlighted that production had dropped by as much as 40 percent in some factories due to inadequate gas supply, which comes from the Titas Gas Transmission and Distribution.

Rashid also pointed to a number of other factors that were keeping the industry from thriving, such as import duty on raw materials ranging from 5 to 25 percent, value-added tax of 15 percent on produced goods, and supplementary duty of 15 percent.

Besides, high interest on working capital and on credit for the procurement of capital machineries pushed the industry into further difficulties.

Against this backdrop, the BCMEA requested the government to take urgent steps to ensure normal supply of gas.

Md Sirajul Islam Mollah, president of the BCMEA, wrote to the Ministry of Power, Energy and Mineral Resources about the gas crisis that has been plaguing the ceramics industry since May.

Mentioning that production was being disrupted, he added that the gas pressure sometimes drops from 2 to 3 PSI to near zero.

Mollah explained that ceramics is a gas-dependent industry and natural gas is one of the primary raw materials. It is used as fuel and accounts for 10-12 percent of the total cost of production.

He also said kilns or furnaces need uninterrupted gas supply for 24 hours to prepare ceramics products since firing is done at 1,200 degrees Celsius.

"Without a certain level of pressure, it is not possible to continue production processes."

When the pressure reduces, all the products inside kilns are immediately destroyed, he stated. Additionally, it takes a minimum of 48 hours to 72 hours to restart the kiln once it shuts down. Sometimes, valuable equipment is destroyed, causing huge financial losses, he added.

Irfan Uddin, director of FARR Ceramics Ltd, said production losses had contributed to lower exports.

"If we do not gas as required, we can't ensure quality of production. It is not possible to export substandard products as it is a matter of the industry's image," he said.

So, the volume of exports reduced substantially this year.

Irfan Uddin, also general secretary of the BCMEA, added that it was unfeasible to use alternative fuel sources like liquefied natural gas or compressed natural gas because it would increase the cost of production by over 25 percent.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments