Advantages of alternative materials over conventional clay burn bricks

Bangladesh is a severely land-scarce country with per-capita cultivable land of only 12 decimals. Bangladesh loses one percent agricultural land annually mainly because of unplanned rural settlements and production of clay burn bricks using fertile topsoil. Such high rates of land loss will not only hamper agricultural production but will have adverse impact on food security. Moreover, production of bricks is destroying forests due to the burning of wood as fuel. Annual brick production is over 25 billion against our national demand of around 20 billion, emitting 20 million tonnes of carbon which is about 20 percent of the country’s total emission. Studies reveal that 58 percent of total pollution in Dhaka is due to over 1,200 brick kilns operating in and around the city during the months of November to February and 1,250 children die every year in the capital city alone. The government is working towards phasing out of clay burn bricks by June 2025.

Alternative building materials and technology

Building material is any material which is used for construction purposes. It may be naturally occurring substances such as clay, rocks, sand, and wood or manmade products such as cement, steel, glass, aluminum, etc.

Alternative building material is an alternative to traditional engineering construction materials such as Hollow Concrete Block, Autoclaved Aerated Concrete Block, Compressed Stabilised Earth Block, Thermal Block, Interlocking Block, Cellular Lightweight Concrete Block, etc. Alternative materials offer both economic and environmental incentives.

Alternative technology is a term used to refer to technologies that are more environmentally friendly than the functionally equivalent technologies dominant in current practice. Alternative building technologies are Ferrocement, sandwich panel, 3D panel, particle board, plastic wood, etc.

Let’s discuss Hollow Concrete Block and Autoclaved Aerated Concrete as alternative materials.

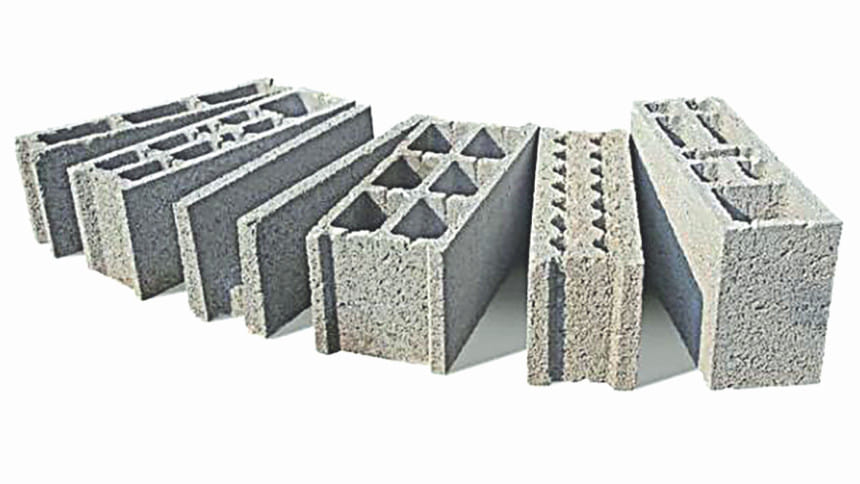

Hollow Concrete Block

A concrete block is one of several precast concrete products used in construction. Most concrete blocks have one or more hollow cavities, and their sides may be cast smooth or with a design. A concrete block is primarily used as a building material in the construction of walls. In use, blocks are stacked one at a time and held together with fresh concrete mortar to form the wall similar to conventional bricks.

Autoclaved Aerated Concrete

Autoclaved Aerated Concrete is a lightweight, precast, foam concrete building material suitable for producing concrete masonry unit (CMU) like blocks. Composed of quartz sand, calcined gypsum, lime, cement, water and aluminum powder, AAC products are cured under heat and pressure in an autoclave.

Advantages of alternative building materials

Lightweight: One of the features of Hollow Concrete Block and Autoclaved Aerated Concrete is their light weight. HCB possesses holes inside and AAC possesses a cellular structure created during manufacturing process. Compared to conventional clay bricks, weight of HCB is 55-65 percent and that of AAC is 25-30 percent only.

Cost-saving: Price of Hollow Concrete Block in the present market is only 75 percent that of conventional red bricks. Moreover, AAC and HCB are light in weight and volume of a single unit is 4.5 times that of a red brick. Lightness saves the cost of structure by reducing member size and steel area and also construction of wall requires less amount of mortar, plaster and fewer number of masons because of larger sized blocks which make it economical. Construction of wall using HCB instead of conventional clay bricks can save more than 30 percent cost.

Environment-friendly: Embodied carbon emission for one HCB is 0.75 kg which is 4.25 kg for red bricks. Emission from AAC is also much lower than that of conventional bricks. Bulk raw materials for both blocks are sand or fly-ash. Moreover, both HCB and AAC reduce the incoming heat from outside of the wall so as to reduce the load of air-cooling system.

More earthquake-resilient: Earthquake load is directly proportional to building weight, i.e. the more the building weight, the greater earthquake force. Therefore, use of lightweight materials ensures more earthquake-resilient buildings.

Faster construction: Light to very light larger sized HCB and AAC blocks with fewer joints facilitate faster construction work. Also, AAC block is very easy to handle, manipulate and use with ordinary tools for cutting.

Better durability: Recommended level of compressive strength (6-15 MPa) and lower range of water absorption (5-10 percent) give AAC and HCB reduced porosity and ensure higher durability.

Internal comport: The porous structure of the AAC blocks and the air in HCB do not allow outside sound, heat or cold inside the house. So, it allows for internal comport by keeping homes noise-free, cool in the summer and warm in the winter which ultimately leads to savings in air conditioning load.

Better maintenance: Absence of any salt in the block and reduced permeability will ensure efflorescence-free surface hence reduced maintenance cost.

Fire-resistant: Fire resistance (endurance) rating value of HCB ranging from 1 hour to 4 hours depending upon equivalent thickness or solid fill cores. On the other hand, depending upon the thickness of the AAC blocks, they offer fire resistance from 2 hours up to 6 hours. These blocks are highly suitable for the areas where fire safety is of great priority.

Versatile: Both HCB and AAC have an attractive appearance and are readily adaptable to any style of architecture which means any design can be achieved.

No salinity: Neither AAC nor HCB contains salinity because basic ingredients are salt-free. As a result, any masonry wall constructed using concrete blocks is free from efflorescence.

Summary of benefits of alternative materials

Economical, better functional efficiency, better durability, ease of construction, better finish, minimum waste, less maintenance cost, less energy intensive, no salt leaching (low maintenance), fire resistant, provide thermal and sound insulation, environment-friendly, indigenous sand used as raw materials, reduction in dead load, reduced air conditioning load, faster construction, assured quality and size, recommended for earthquake resilient buildings.

Mohammad Abu Sadeque PEng is Executive Director, Center for Housing and Building Research (HBRC).

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments