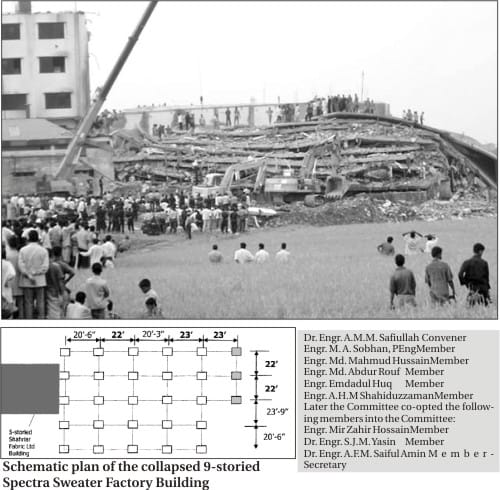

Savar Spectra sweater factory failure

One 9-storied sweater factory building owned by Spectra Sweaters Ltd., located at Palashbari Village under Savar Thana of Gazipur District collapsed in the early hours (1.15 am) on April 12, 2005 killing more than 60 and injuring more than 100 workers. The nation was deeply shocked by the incident. The Honourable President and Prime Minister of the Government of the Peoples' Republic of Bangladesh visited the site a short time after the incident. The site was also visited by political leaders, members of IEB, RAJUK, BGMEA, BUET, BACE and other concerned organizations a short time after the incident and several times later. Separate investigation committees were formed by different organizations to find out the causes and frame comprehensive recommendations to prevent this type of failure in future.

This report has been prepared on behalf of IEB by a Committee constituted by it but does not necessarily reflect the opinion of the IEB.

Description of the incident

On the eastern side of the Kaliakoir-Nabinagar Highway is the 5-storied Shahriar Garments Factory building, which is unaffected. The collapsed 9-storied building is located east of the Shahriar Garments Factory and adjacent to a ditch further towards the east. Both the factories belong to the same owner. The collapse took place in a sudden failure without any warning.

Soon after the collapse the Fire Brigade, Engineers Corps of Bangladesh Army, and other different agencies started the rescue operation, which continued for 8 days (up to the 19 April 2005) till all the debris over the fallen building was cleared/all the trapped victims were rescued, and the dead bodies were recovered.

The IEB Investigation Committee

Soon after the incident, Institution of Engineers Bangladesh formed an Investigation Committee to investigate into the causes of this catastrophic failure. The Committee consisted of the following members:

As per the terms of reference of IEB, the Committee is to "find the causes that triggered the failure process and resulted in complete collapse of the structure". The committee further extended its scope to make recommendations so that such situation can be prevented in future.

Methodology used for the investigation

The investigation has been conducted based on information received through the owner, news media, available photographs, field visits, and critical observations made during the rescue operation and after removal of debris of the collapsed building from the site. The following steps were taken to find out the cause(s) of the disastrous collapse of the building:

Step-1 A layout plan and design prepared by the Engineer employed by the Owner was obtained.

Sep-2 In absence of the As-built drawings, the building's layout plan was reconstructed from the visible column locations after the site was cleared.

Step-3 A pre-design soil boring report (of March 1999) used by the designer was collected from the owner. Subsequently a report on the post-failure field investigations including SPT bore log prepared on behalf of BGMEA was collected and super-imposed over the pre-design bore log.

Step-4 The test results of some materials of the collapsed building (tests performed at BUET Laboratory) were obtained for analyses.

Step-5 An account of additional installations in the building and loading conditions prevailing at the time of collapse was reconstructed by interviewing some workers who were on duty at the time of the incident.

Step-6 A description of the piling work and sinking operation of the two tube wells adjacent to the pile foundations was obtained through interviewing the piling and tube well sub-contractors for use in the review and analysis.

Step-7 A three-dimensional finite element model of the structure was developed to simulate different probable failure modes and verify those with the post-failure revelations, based on the re-constructed layout plan, post-failure survey information and design sheets provided by the design engineer.

Step-8 The design of the respective foundations was checked to assess their design adequacy. To this end, the capacity of the pile groups was calculated based on the both pre-failure and post-failure soil exploration reports.

Step-9 After completion of the normal clearance of the debris, foundation of the ff northeast end corner column and the pile cap was exposed by additional removal of debris and excavation. The conditions thus revealed gave evidence as to how collapse of the building was initiated.

Observation bases formulated during the investigation

The following observation bases were formulated through field investigations, measurements, review of design reports and press reports regarding the nature of failure and the immediate factors that caused it:

(i) The failure of the building took place in a very short time and without any warning; so, the trapped people didn't find adequate time to come out.

(ii) The structural frame for the building consisted of flat slabs supported by columns with no beams at any location. Thereby, while the columns of the floors collapsed and the heavy slabs fell one over another keeping little gap in between, killing most people trapped inside.

(iii) The lift core at west end of the building apparently was not connected with the main building, and so wasn't immediately pulled down by the falling slabs but it finally fell on the top of the slabs.

(iv) The roof slabs of the collapsed structure showed that the general motion of the building during collapse was significantly to the eastward direction. Furthermore, a strong sway of the collapsed roofs of the building was noted towards the northeast direction.

(v) It was observed after debris clearance that the north-east corner of the ground floor slab had gone down by about 11 feet from the surrounding surface and there was little settlement of rest of the floors or footings.

(vi) At the time of failure the building was subjected to all possible live loads associated with full operation of a factory. It is alleged that brick and building materials were staffed at the top floor during construction.

(vii) There were two deep tube wells operating within the building. One deep tube well had been installed long before the collapsed building was constructed and the other deep tube well was installed about three months after the bored piles were cast and located within as close as about 10 feet of the north-east column that sank.

(viii) It is alleged that there had been noise of the compressor housed within the building with perceptible vibration of the floors (this however could not be verified).

Failure speculations and investigation committee findings

Media guesses about failure: Many guesses about the causes came out through the media immediately after failures, a few of which are listed below:

(i) The building collapsed due to bursting of the boiler.

(ii) The building was constructed on the soft soil and in the ditch/khal and the cast-in-situ bored pile foundation has failed.

(iii) The quality of concrete and other construction materials, and workmanship was poor.

(iv) The building was designed for 4-storeyed but the construction was done for 9- storied, and thus the building was overloaded.

(v) The structure was constructed without any proper and sound design.

(vi) The construction wasn't supervised properly.

(vii) The contractor didn't follow the design drawings.

(viii) The design was faulty.

It's natural that immediately after such a catastrophic collapse such guesses would appear before the nation. The Committee however looked into each of these possibilities and by eliminating improbable ones tried to arrive at the root causes of this disastrous failure.

IEB Investigation committee findings

Boiler blow out: The issue had been investigated and was discarded because the boiler was found in un-burst condition after the incident.

Failure of foundation: As stated earlier, it was observed after clearing the debris that none of the pile caps including that of the north east corner column showed any sign of undesirable settlement or failure. Therefore, the assumption that the failure resulted from weak soil condition and foundation failure is discarded.

Overloading of the building: According to media reports, the building might have been overloaded on two counts, either the construction was made for higher stories than the structure was designed for and/or, the service load far exceeded the design loading. Design reports received from the designer shows that the structure was designed as an eight-storied building but a portion of the building was constructed as nine stories. Loading in excess of the design load is likely but the extent of overloading could not be confirmed.

Large variation in quality of concrete: There has been considerable variation in concrete strength as found from test results (tests done by BUET testing laboratories) using random samples from columns and slabs. This reveals systematic and proper quality control operations were not performed in constructing this building. Also the onsite investigations suggests that the quality of construction materials used in this project didn't satisfy the specification requirement. It was observed that the brick chips were used as coarse aggregate whereas the designer specified stone chips for it. However, it should be noted that strength of samples taken belonged to the collapsed structure; therefore, some deterioration in strength could be associated with the collapse.

Non-availability of approved design and As-built records: No approved architectural or structural drawings could be found for the building. There has been some confusion as to whether the collapsed factory building and the surrounding area are under the jurisdiction of the Savar Cantonment Board or RAJUK. The factory owner in an interview mentioned that he contacted the Cantonment Board for permission to construct an eight storey building but some officers of the Board suggested him that the Board would not approve such high rise building at the moment and that he should apply for a four storied building. He was suggested that if the design had been made for an 8-storied building and he constructed only four stories at that time, he might later apply for higher storied building and would possibly get the approval. Therefore, the Owner employed a graduate engineer to design an 8-storied building of which he initially constructed four stories only. Later, without any approval he extended the building to eight stories with a stair room above. A copy of the design received from the designer of the building suggests the building has been designed for eight stories. Some differences were found between the dimensions and specifications shown in the design layout sheets and that actually built.

The documents which could be obtained from the designer were incomplete for design review. It appears that the building was designed sometimes in April 2000, about 5 years back from the date of failure. The designer relied on a flat plate-column system as structural form and adopted no beams in the system. Among the 33 columns, most of them were founded on bored cast-in-situ piles. However, the columns of extreme west side bay were founded on pre-cast micro-piles. All the floors of the building consisted of flat slabs about 9 inches thick. Although some reinforcement arrangements for slabs are given, no reinforcement and connection details between columns and slabs could be obtained from the designer's design sketches.

Design deficiency: Some design calculations and sketchy drawings were obtained from the designer of the building. A review of these calculations suggests some inadequacy in the design assumptions, load considerations and detailing.

Review of the structural analysis and design

Pile foundation: The designer chose groups of 20-inch diameter, 65 ft long piles as foundation of each column. For each individual pile, the allowable capacity estimated by the designer based on the pre-design bore log of Fig. 6 was 98 metric tons, of which 40 tons was given by friction and 58 tons by end bearing. The pile cap levels below all the columns were not at the same elevation as observed after exposing the pile caps below three columns.

The pre- and post-failure bore logs located near the north-east corner column of the collapsed building showed almost identical sub-soil profile, including soft clay layer in the upper portion. An estimation of the allowable bearing capacity of the above pile based on this sub-surface soil profile showed it was adequate. As stated earlier, the physical observations did not show any defect or settlement of pile caps of the building.

Structural frame and post-failure design review: Although designer's sketchy drawings showed some reinforcement arrangements for slabs, no reinforcement and connection details between columns and slabs could be obtained from these. The Investigation Committee prepared an as-built layout plan of the building.

The area over which the building was constructed is undulating and the pile cap levels for the constructed columns differed considerably. Also it was found that no grade/tie beams connected the columns at footing level. Cross-sections of the columns were not uniform throughout their respective heights and were reduced gradually in the upper floors.

As per unofficial record, the pile reinforcement consisted of six 20 mm dia. deformed bars tied by a 10 mm spiral reinforcement spaced at the rate of 4 to 6 inch centres. These however could not be verified.

Numerical model of the building for post-failure design review: With a view to find out the real causes of failure, the investigation team first attempted to make an independent design of the structure by taking into consideration the as-built column layout, adopted flat plate-column structural system, material specification mentioned in the designer's design sketches, end use of the constructed facility and site location. To do this, a finite element model of the structure was developed in ETABS Version 8, a general purpose finite element analysis and design software. The Bangladesh National Building Code (BNBC 1993) was consulted to assign the dead load, vertical live load, wind load and earthquake loads in the process of analysis.

Reconstructing the collapse sequence in the model: In order to reconstruct the collapse sequence and thereby to narrow down the number of failure hypothesis, the investigation team employed pushover analysis technique and conducted painstaking nonlinear analysis. To this end, the primary direction of movement of the collapsed structure as revealed during the first-day field surveys and noted earlier was taken into prime consideration. Thus the investigation committee drew the final failure hypothesis that either the failure of the northeast corner column or its foundation system might have triggered the collapse phenomena. Based on this hypothesis, the support of the northeast corner column was removed from the numerical model to replicate the probable incident. To make the analysis as much closer as possible to the reality, the geometric nonlinearity and large deflection effects were considered in the process of analysis. The pushover analysis conducted this way generated some interesting findings from the developed numerical model and matched with the field survey findings. The investigation process took a forward motion.

(Part II shall appear next Friday 12 October 2007)

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments