Status of biogas technology in Bangladesh

Bangladesh is one of the low energy consuming countries of the world. At present, the per capita energy consumption is 220 kgoe. The national grid could so far cover only 35 per cent of the total population, and only 3 per cent people are enjoying piped gas supply. About 70 per cent people of Bangladesh live in rural areas, where the situation is worse. As a result, rural to urban migration is high in Bangladesh.

In the rural areas, the houses are scattered. Neither grid nor piped supply is suitable for those areas. Decentralised supply systems like solar, biogas; wind, etc. have no alternative. About 90 per cent of the electricity now produced in the country is based on natural gas, which has limited reserves and will be exhausted in the near future.

It means that when our gas reserves are exhausted there will be no electricity. To face this grave situation, finding alternative or renewable sources of energy is the only option. Biogas technology may be one of those.

Bangladesh has a wonderful climate for biogas production. The ideal temperature for biogas is around 35 deg. The temperature in Bangladesh usually varies from 6 deg. to 40 deg. But the inside temperature of a biogas digester remains at 22 deg.-30 deg., which is very near to the optimum requirement.

Raw materials for biogas are easily and cheaply available everywhere. All the hazardous materials that pollute the environment spread bad smell and diseases are raw materials for a biogas plant. Biogas is produced through fermentation of organic matter in an anaerobic condition. So, the process does not only produce gas, but also kills all harmful bacteria.

It is decentralised and appropriate for the rural areas, where neither piped gas supply nor grid electricity supply is possible. Biogas has multiple advantages. It can meet the need for both gas and electricity. At the same time, it gives valuable organic fertiliser. Biogas is an old technology invented by Alexandra Volta in 1776 in Com, Italy.

He collected gas from the bubbles coming up due to stirring of organic sediments deposited at the bottom of an old pond and discovered its combustibility. The technology was at the research stage for many years and got momentum only after the fuel crisis in 1973.

At present, it is widely used in many countries including China, India, Nepal, Vietnam, Cambodia, Thailand etc. There are now about 20 million biogas plants in China, 4 million plants in India, and about 0.16 million plants in Nepal.

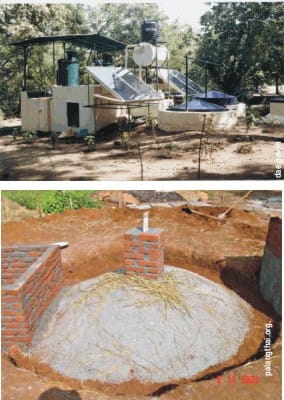

In Bangladesh, the first biogas plant was set up by Dr. M A Karim, a professor of Bangladesh Agricultural University (BAU), Mymensingh, in the University campus in 1972. It was a floating dome type plant of 3m3 gas production capacity.

Subsequently, seeing the success of the plant, 4-5 more plants were constructed in the surroundings. These plants did not last long due to leakage in the domes.

In 1974, the Bangladesh Academy for Rural Development (Bard) constructed one biogas plant following the same design. The Institute of Fuel Research and Development (IFRD) constructed another plant in the campus of the Bangladesh Council of Scientific and Industrial Research (BCSIR) in 1976, followed by a plant at the KBM College in Dinajpur in 1980.

As the construction costs were high and no subsidy was available, the technology did not have any attraction for the common people. In 1981, the government established a department named Environment Pollution Control Department (EPCD), through which they started a program at a cost of Tk. 34 lacs.

Under the project, about 150 floating-dome and 110 fixed-dome plants were installed until 1984. The floating-dome plants initially worked successfully, but did not last long due to lack of after-sale service and leakage in the gasholder. The fixed dome plants did not work even for a day due to design fault. This has created negative impact among the common people as well as the policy makers.

During this period, at the initiative of the then chairman of BSCIC, Mr. Sirajuddin, some engineers of the organisation were trained with technical support from BCSIR, and constructed 92 plants. The Department of Livestock (DLS) also trained many of its engineers on biogas technology and constructed about 70 plants by 1990.

Some NGOs like Danida, Brac, Grameen Bank etc. took initiatives to popularise the technology. These NGOs, with technical support from BCSIR, constructed about 250 biogas plants in districts of Bangladesh including, 17 bag type digesters by Grameen Bank.

These plants also did not last long. Under the "Fuel Saving Project" implemented from 1989 to 1991, IFRD trained local youths who constructed 126 plants in the premises of well-to-do farmers. The gasholder was supplied free of cost. The plants were floating-dome type, but they did not last long.

LGED constructed their first floating-dome model biogas plant in Kurigram district, and arranged a seminar there on December 27, 1986. About 300 scientists, experts, engineers, politicians, and persons interested in biogas technology joined the seminar.

Until 1992, they constructed 7-8 plants following the same design. The plants initially worked successfully, but after 4-5 years went out of order due to leakage in the gasholder, pipeline, and burner.

In 1989, one scientist named Mr. Shamsul Hoque of BCSIR received training on biogas technology from Biogas Research and Training Centre (BRTC), Chengdu, China. After coming back, he constructed one fixed-dome Chinese model biogas plant at BCSIR campus.

Till today, the plant is working successfully. Following the design, one LGED engineer constructed two biogas plants in Noakhali in 1992, with financial support from Danida. These plants are still in operation.

Subsequently, one engineer of LGED and Mr. Shamsul Hoque of BCSIR constructed about 50 fixed-dome type biogas plants in different districts at the cost of the users, and thus the fixed dome model biogas plant was introduced in Bangladesh.

LGED, under Slum Improvement Project and Secondary Towns Infrastructure Development Project, constructed about 100 plants during the period 1992-1996. A MoU was signed between BCSIR and LGED in 1993, and about 70 engineers have been trained under the agreement.

In 1994, LGED supported the establishment of an ecological village (Amgram in Madaripur district), and constructed 15 domestic biogas plants using night soil, kitchen waste, water hyacinth etc.

An important distribution push was delivered by the "Biogas Pilot Plant (1st phase) Project" implemented by BCSIR in the period July 1995 to June 2000. In total 4,664 fixed-dome plants were constructed throughout the country.

BCSIR employed and trained 128 diploma civil engineers who were assigned responsibilities for motivation, installation, and after sales service throughout the country. In addition, 898 youths were trained to support the project. The biogas farmers received an investment subsidy of Taka 5,000 under the project.

MoUs were signed between BCSIR and several other institutes like Brac, LGED and DLS for research, training, and dissemination of the biogas technology. An interim evaluation report in 1999 reported that 99% of the plants installed under the project were in operation, while 91% of the owners could meet their household fuel demand through biogas.

Bio-slurry from the biogas plants was used in horticulture, pisciculture, and agriculture. The average saving per plant amounted to Taka 759 per month (BCSIR, June 2001).

As the 1st phase was successfully completed, and the potential for biogas in Bangladesh considered huge, BCSIR implemented the 2nd phase of the Biogas Pilot Plant in the period July 2000 to June 2004.

The target for this phase was put at 20,000 biogas plants, out of which 17,194 plants were finally built. The investment subsidy for the owner was increased to Taka 7,500 per plant. In addition to the diploma civil engineers employed and paid on a monthly basis by BCSIR, an agency system was introduced on incentive basis.

About 50 agencies were recognised in defined areas (mostly districts), and received a lump sum fee of Taka 5,000 per plant as service charge. About 128 engineers and 250 local youths were trained for 10 days under the project. About 1,000 masons have been trained as well.

LGED, inspired by the then agriculture minister Matia Choudhury, launched a pilot project to construct 5,000 domestic biogas plants in the country. During the period from October 1998 to June 2003, they constructed 1,120 biogas plants under the project.

As the investment subsidy for this project amounted to Taka 5,000 only, it proved to be rather difficult to motivate farmers during the implementation of the 2nd phase of the Biogas Pilot Plant Project when BCSIR was providing Taka 7,500 as subsidy.

Therefore, the LGED project was terminated prematurely. Under the Secondary Town Infrastructure Development Project-II, another 20 community biogas plants were installed, which used human excreta only.

In 1994, the government of Bangladesh created a public limited company named Infrastructure Development Company (IDCOL) with financial assistance from the World Bank to support all kinds of infrastructure development, with focus on energy related infrastructure.

They successfully established 450 MW power plants at Meghna Ghat, installed 125,000 solar home systems since 2003 and, recently, with support from Netherlands Development Cooperation (SNV), launched a project for the extension of biogas technology in Bangladesh.

Under the program, 36,450 biogas plants will be built by the year 2009. 16 partner organisations have been identified for the implementation of the project. By now, they have constructed about 2000 plants.

Grameen Shakti (GS), a member of the Grameen family, incorporated in 1996 as a "not for profit company" to promote, develop, and popularise renewable energy technologies in the remote rural areas of Bangladesh.

At present, GS has about 800 engineers and 1000 field staff, serving more than 600,000 beneficiaries through its 300 unit offices, 44 regional offices, and 6 divisional offices. It has installed more than one hundred thousand solar home systems.

For its contribution towards popularising solar technology, GS has won several international awards, such as "The Energy Globe Award," 2002 from Austria, "European Solar Prize Award," 2003 from Germany, "Best Theme Award," 2003 from Usaid, "Solar Prize," 2004 from a government owned company, and " Best Organisation Award," 2005 from the prime minister of Bangladesh. In 2006, GS received "Ashden Award" from UK.

In early 2005, they launched a program for the extension of biogas technology in the country. Until June 2007, they had constructed more than 1000 biogas plants in different districts of the country.

Grameen Shakti has two systems for the biogas extension program. For small family size biogas plants, i.e. 1,6m3 - 4.8 m3 gas production per day, they give subsidy of Tk.7,000; and for bigger size plants they do not give any subsidy.

For any biogas plant, GS provides loan without collateral, and recovers it in 24 equal monthly installments with 6% service charge. Recently, Grameen Shakti has been providing technical and financial support for the generation of power using biogas. Instead of developing a new type of generator, GS is using the available gas, petrol, and diesel generators for producing electricity.

Although biogas technology is getting increasing attention all over the world, the use of bio-slurry is still neglected. Giving priority to the bio-slurry, IDCOL renamed their project title, and Grameen Shakti appointed one expert exclusively for the promotion of bio-slurry. But still, in most cases, bio-slurry is not properly used. It is mainly because of the ignorance of the farmers. Recently, Grameen Shakti has taken a decision to demonstrate use of slurry in different districts, so that the farmers become interested in using bio-slurry.

During the last 60 years, rural to urban migration in Bangladesh increased alarmingly. In 1951, only 2.5% people lived in urban areas, which has now risen to 30%. The population of Dhaka city was 0.35 million in 1951, and it is now more than 10 million. Dhaka has now become the 8th mega city in the world.

According to the UN Population Division, Dhaka will be the 2nd mega city in 2015. It is because of the fact that all energy supplies are limited to urban areas. Biogas has potential; it is proven, but highly neglected in Bangladesh.

At present, there is no government program for the extension of biogas technology. There is no government agency to deal with renewable energy issues, although the government of Bangladesh signed the millennium declaration and agreed to raise its renewable energy share to 10% by 2015. The year is not too far, but the share of renewable energy is far below the target.

M.A. Gofran is Biogas Consultant, Grameen Shakti.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments