Fly ash: A new pollutant or resource?

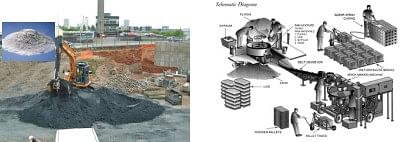

L-R: Fly ash generation from plant. Fly ash brick making plant. inset- Fly ash

Five coal fields have so far been discovered in Bangladesh having substantial amount of bituminous to sub bituminus coal. Out of five coal fields, Barapukuria is in production and its coal is being used for power plant while Phulbari and Khalashpeer coalfields are expected to undergo in production in near future. Barapukuria coal based power plant is producing reasonable amount of high quality non-toxic fly ash. Proper fly ash capturing, storing, utilisation and proper management can turn it into a resource that can change the future of Bangladesh.

Lately fly ash has become an environmental pollutant issue but in real world most people do not know at what point and how the environment, economy and social life of the surrounding area become vulnerable to fly ash. Is there any chance to mitigate its impact or convert it into a resource? In this article the writer attempts to answer the question.

Actually fly ash is produced from burnt crushed coal from coal-fed power plant which is fine-grained, powdery particulate material. If the fly ash is directly let out in the environment than it could be a matter of grave concern. But generally fly ash is captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneys of the coal-fed power plant.

Irrespective of the chemical, physical and petrographic property of the burned coal in the power plant, usually all fly ash includes substantial amounts of silicon dioxide (SiO2), aluminium oxide (Al2O3), iron oxide (Fe2O3), calcium oxide (CaO), and carbon content is represented by the loss on ignition (LOI). Sometimes it may contain toxic constituents as trace materials up to a considerable percentage depending upon the specific coalbed makeup and in that case it could be a threat to the environment, but mitigating its impact is very much possible.

Lately most of the electric power plants happen to be coal fed. As a result huge amount of fly ash is being produced which is a matter of concern for of course a waste management department. Waste utilisation is the best option for pollution-prevention and during previous decades new doors have been opened for fly ash utilisation in various sectors like manufacture of cement, bricks, pavement materials, floor tiles, wall panels; in agriculture, road construction, land-filling and back-filling of mines, etc.

There are two classes of fly ash -- Class: F and Class: C and the classification depends on the main component of the ash. Indeed class F fly ash is an unparalleled, high quality, and consistent product that provides tremendous value to the ready mix industry.

Fly ash in portland cement concrete: Fly ash has been successfully used as supplementary cementitious material in Portland Cement Concrete (PCC) for nearly 60 years. This is the largest single use of fly ash. It can also be used as a feed material for producing Portland cement and as a component of a Portland-pozzolan blended cement. Portland cement produces 1 ton of CO2 per ton of cement during its manufacture while one ton of fly ash can replace one ton of Portland cement thus emitting one less ton of CO2 into the atmosphere. In addition to economic and ecological benefits, the use of fly ash in concrete improves its workability, reduces segregation, bleeding, heat evolution and permeability; inhibits alkali-aggregate reaction, and enhances sulfate resistance.

Fly ash in flowable filling: Flowable fill is a slurry mixture consisting of sand or other fine aggregate material and a cementitious binder that is normally used as substitute for a compacted earth backfilling. Fly ash has been used in flowable fill applications as a fine aggregate and as a supplement to or replacement for the cement. The quality of fly ash used in flowable fill applications need not to be strictly controlled, both dry and reclaimed ash from settling ponds can be used and no special processing of fly ash is required prior to use.

Fly ash in embankment: Fly ash has been used for several decades as an embankment or structural fill material, particularly in Europe. Fly ash in this application must be not too dry and dusty or too wet and unmanageable. When fly ash is at or near its optimum moisture content, it can be compacted to its maximum density and will perform in an equivalent manner to well-compacted soil.

Fly ash in asphalt mix: Fly ash has been used as a substitute mineral filler in asphalt paving mixtures for many years. Mineral filler in asphalt paving mixtures consists of particles, less than 0.075 mm (No. 200 sieve) in size, that fill the voids in a paving mix and serve to improve the cohesion of the binder (asphalt cement) and the stability of the mixture. It addition, fly ash that have a high lime (CaO) content may also be useful as an antistripping agent in asphalt paving mixes.

Fly ash in stabilized base: Stabilised bases are mixtures of aggregates and binders, such as portland cement, which increase the strength, bearing capacity, and durability of a pavement substructure. Because fly ash has got pozzolanic properties/self-cementing properties, it can be successfully used as part of the binder in stabilised base construction applications. When pozzolanic-type fly ash is used it does not require any activator, otherwise an activator must be added to initiate the pozzolanic reaction.

Moreover, recently in the domain of agriculture fly ash is being used successfully in soil amendment, fertiliser, cattle feeders, soil stabilisation in stock feed yards and agricultural stakes.

It is time to take example from USA, UK, Sweden, Spain, the Netherlands, China, Japan, Germany, France, Canada as they are utilising fly ash for different productive purposes (like in Portland cement concrete, Portland cement clinker, Pozzolana, admixture in concrete, fine aggregate for mortar and bricks etc) and apply it in Bangladesh for the benefit of the nation-- environmental and economic.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments