The green apparel maker

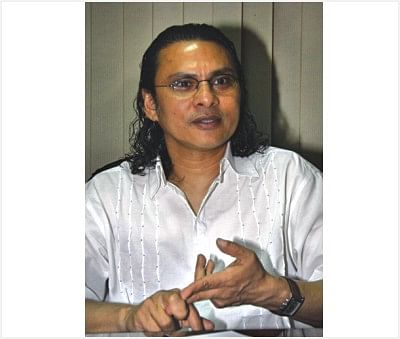

Shafiq Ul Hassan

Three major issues -- environmental protection, compliance and ethical business practices -- must be addressed to sustain fierce competition in Bangladesh's apparel business.

Strict implementation is paramount now, observes Shafiq Ul Hassan, managing director of Echotex Ltd, an export- oriented readymade garments factory.

The same is true for international buyers, as they are the consumers, he adds.

"Otherwise, you'll not survive in the business for long," he says.

The Metropolitan Chamber of Commerce and Industry recently awarded Hassan in recognition of his contribution in saving the environment through ethical business practice.

The company was also nominated last week for the National Environmental Award 2010 from the environment and forest ministry.

Hassan, a chemical engineer from the UK, set up an effluent treatment plant (ETP) at his factory in Chandra Polli Bidyut at Kaliakoir, Gazipur, on the very first day of its operations to keep environment pollution at bay. Echotex, a British-Bangladesh joint venture, was established in 2009.

ETPs are used in factories to drain chemical dyes so as not to destroy the quality of water, animal and fish species.

Hassan says many garment owners in the country began operations without ETPs. However, on pressures from the government and foreign buyers, now many move to set up such treatment plants.

The planet does not belong to an individual -- it belongs to inhabitants of the earth, he says. "So, it's the responsibility of all to save the environment."

"It's very easy to destroy, but very difficult to build," Hassan says. He has plans to invest $1 million to update the ETPs in his factory in the next three years. At present, the company is able to dye 15 tonnes of fabric a day. 7.5 lakh litres of water is treated in the factory everyday.

The proposed updated ETPs will have a zero discharge capacity, meaning the treated water would be so pure that anybody can drink it, the Echotex MD says.

The company also has plans to expand operations in the next five years, as growing demand from international buyers backs the sector, he says.

Around 30 lines, or 1000 more sewing machines, will be added to the existing 30-line factory.

At the same time, the company also plans setting up a spinning mill, according to Hassan. It eyes $22 million turnover this fiscal year.

Echotex is not Hassan's first venture in apparels. He has been running Echo Sourcing, an outsourcing British-Bangladesh apparels company, with his British partner Para Hamilton, since 1996.

Hamilton, chairperson of both Echo Sourcing and Echotex, supervises product designs from the company's London office.

Echo Souring purchases 95 percent of Echotex's production.

Last year, Echo Sourcing earned $35 million from the sale of goods. Its major buyers are New Look, Debenhams, Fat Face, Peacock and Primark, Hassan says. Echotex mainly produces printed women's T-shirts.

Born in a remote village in Sunamganj in 1958, Hassan left for the UK in 1971, when he was a student of class VII at Saint Gregory School, Dhaka.

He previously worked for Fair Pattern Ltd, a UK-based sourcing company, and later for Brac, a Bangladeshi nongovernmental organisation, before starting Echo Sourcing.

"I worked day and night to set up Echo Sourcing," he says, adding that the company made a lot of profit when New Look started placing orders in bulk quantity.

The company won the hearts of buyers for quick delivery of orders, he adds.

"We used to outsource a lot of apparel items during the early years of operations. At that time, buyers used to give only 15 days of lead-time. We were somehow able to send the items before this 15-day lead time," he says.

Now, the number of Echotex's working employees reaches 4,000 from 300 at the beginning.

Being a compliant factory, it never faced labour unrest as it paid salaries and other benefits to its workers on time. Moreover, the company serves lunch to 4,000 members of the staff a day.

Serving lunch has double benefits -- it saves working hours and ensures good health of the workers, Hassan says.

“Workers' welfare is the main practice of the company's corporate social responsibility.”

The instigation of unrest by outsiders is a major concern for the garments sector, he says. "Other concerns, like a shortage of energy and power and poor infrastructure, are manageable, but influence from outsiders is difficult to manage."

According to Hassan, business should not become big for the sake of becoming big -- it should incorporate environmental protection and ethics. "Business, not in volumes, but for quality."

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments