Two new units of Premier Cement remain idle for pandemic

Premier Cement is yet to begin production at two of its new manufacturing units despite getting fully prepared in March, as a few key foreign experts and workers of the company could not return to Bangladesh due to the Covid-19 outbreak.

"We could not start production within the stipulated time due to the absence of some technical experts and workers from China and Denmark," said Mohammed Amirul Haque, managing director of the cement maker.

After operating on a trial basis for a month, the units were scheduled to go into commercial production in June.

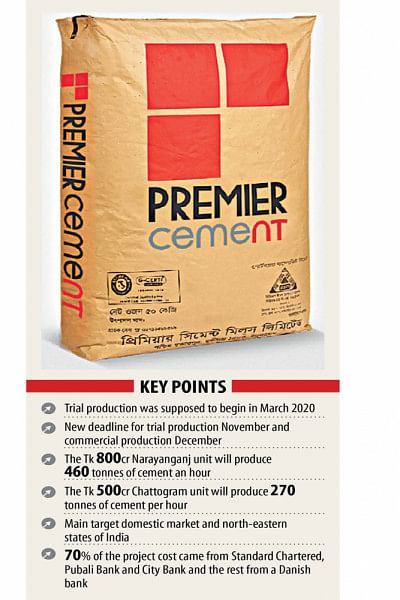

One of the units was developed in Narayanganj at Tk 800 crore and the other one in Chattogram at Tk 500 crore, he said.

Although both of the factories are lying unproductive at this moment, the company has to set aside a certain amount every month to carry their fixed expenditures, Haque told the Daily Star.

Now, the cement maker expects to begin trial production in November and commercial production in December.

The new factories were established with an aim to double the company's annual production capacity and capture a greater share of the domestic market as well as the northeastern states of India.

The expansion plans were taken way back in 2017 after foreseeing the demand hike within 2021, Haque said.

Demand for cement has grown constantly by about 15.6 per cent for the last eight years due to the government's mega development projects.

The company was set to issue a disclosure to the Dhaka Stock Exchange following its annual general meeting during the last quarter, he added.

Standard Chartered bank, Pubali Bank and City Bank funded 70 per cent of the project's cost as loans while a Danish bank provided another $35 million, or Tk 280 crore, for the purchase of capital machinery.

Haque claims that the expansion of their annual output from 2.4 million tonnes to 5.2 million tonnes will be a record for a single entity in the country.

Vertical roller mills, a product of Danish company FLSmidth which can generate extremely fine powder using 20 per cent less power, will be used to produce 460 tonnes and 270 tonnes of cement per hour in Narayanganj and Chattogram units respectively.

Besides, the company hopes to double the number of staff from the existing 1,100 across its five units.

Despite having many challenges in the sector, Premier Cement has always been profitable and provides handsome dividends to its shareholders, Haque said.

The cement business provides no scope for quick profits so interested businesspeople should think twice before stepping into the industry, he added.

Haque also claimed that his brand accounts for around 25 per cent of Bangladesh's cement export to India.

Premier Cement has been supplying cement to 62 ongoing development projects of the government, such as the Padma bridge and Karnaphuli tunnel, he said.

There are 37 active cement factories in Bangladesh with a combined investment of over Tk 30,000 crore.

The sector has an annual production capacity of 58 million tonnes against a domestic demand of 33 million tonnes.

Local companies dominate the market, where annual sales have reached $3 billion, or Tk 25,500 crore, according to data from the Bangladesh Cement Manufacturers Association.

Of the total consumption, individuals account for 25 per cent, real estate companies and developers 30 per cent and the government 45 per cent.

Bangladesh's per capita cement consumption is currently around 181 kilogrammes but is expected to increase to 220 kg by 2021.

Haque believes that cement manufacturers will be benefited in the days to come if some existing challenges are removed as the demand for the key construction material will only increase alongside the rising trend of economic activities.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments