Standard materials for safe construction

Mahfuz Anam

Editor and Publisher,

The Daily Star

Maintaining standards for construction is a responsibility which is not easy to undertake yet is of great importance. The longevity of the structures should be prioritised when it comes to construction projects. Construction should have no option for compromise of standards. That way, public safety and interest can be safeguarded.

A legal framework is pivotal when it comes to construction; the framework must be clear, simple and implementable. Current construction projects are being conducted under the existing legal framework. However, there is room for improvement.

The Bangladesh Standards and Testing Institution (BSTI) maintains and monitors construction quality. However, BSTI needs to be enriched and empowered so that it can strengthen its hold on its responsibilities.

Tanjim Ferdous

National Consultant, United Nations in Bangladesh, and Moderator of the Session

Structures like Bangabhaban and Curzon Hall have been around for a long time. Hardinge Bridge was opened back in 1915, and to this day it is still standing strong. Contrarily, the destruction of Rana Plaza has caused thousands of deaths. Therefore, today's discussion on safe construction is critical.

M Firoze

Adviser, Marketing & Product Development, BSRM

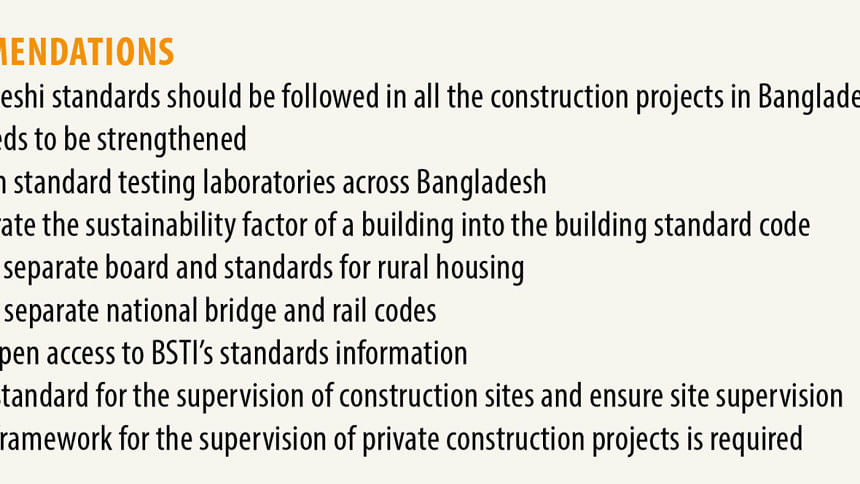

Even though BSTI exists, construction projects still do not follow the proper standards. The "Padma Bridge Rail Link Project" is the largest construction project in the country, worth 40,000 crore taka. There is valid proof of Indian standards being followed for the construction materials used in this project instead of Bangladeshi ones. The contractor China Railway Group Limited, also known as CREC, has given the order. This is unthinkable for such a large project in our own country. Bangladesh Railway, the state-owned rail transport agency of Bangladesh, is the owner of the project. They should have had an engineering committee to decide on the standard issue.

The Padma Bridge project, which is worth 30,000 crore taka, also follows a British Standard code of practice for general structural use of plain and reinforced concrete. The fact that major projects run by our government are adhering to foreign standards is concerning. Most of the government's 12 fast-tracked projects is using Bangladeshi standards. In Bangladesh, we have an ISO-based standard. It is as good as any foreign standard. We could have used our own standards and conducted our projects safely in that manner.

Any sustainable structure must be made of quality materials regardless of its durability. Steel, concrete, and cement cannot be produced without a mandatory licensing system. Therefore, we must follow the standards of the country we reside in; it is not possible to follow the standards of other countries. Legally too, the material standards must comply with the BSTI standards. Compliance issues must start with the basic materials at the grassroots level.

Bangladeshi citizens are not permitted to access any information regarding BSTI's standards without disclosing their personal information to the BSTI website in detail along with payment. Whereas, the Bureau of Indian Standards has made Indian standards available online, where the public may access it with a mere Google search. The dissemination of information in Bangladesh is much more rigid. This makes it more difficult for us to take our standards to the next level.

Dr Md. Tarek Uddin

PEng., Professor, Department of Civil and Environmental Engineering (CEE), Islamic University of Technology (IUT)

Different standards are adopted for projects around Bangladesh. It is important that experts in the industry take the initiative to implement Bangladeshi standards only and make it known to everybody that this is the route we should take.

On World Standards Day, we appreciate the work done by researchers and academics to produce different standards. We must respect both national and international standards. We cannot function without maintaining standards, and so they are pivotal for the progression of our projects.

Proper legislation related to following standards is essential. Licensed engineers are required for supervision. Lack of skills is an issue in Bangladesh, and engineers are not exempt from it. We need to provide licenses for supervision, structural design, and other relevant fields of work. Our engineers must be familiar with the long-term service life of a structure.

We consume 33 billion tonnes of concrete and 4,000 million tonnes of cement every year worldwide. That is 12 kilograms every day. Global crude steel production is about 2,000 million tonnes. Our natural resources are being depleted. Future generations may not get access to the materials they need. This is why a sustainable approach is required. Re-using materials and creating designs for long, sustainable production lives is the way to go.

As an academician, I must add that our graduates must be given the proper knowledge to be able to make positive impacts in the real world. They must value the society and environment.

Engineer S M Khorshed Alam

President, Bangladesh Association of Construction Industry (BACI)

A purchase order from CREC was made for the "Padma Bridge Rail Link Project." In the purchase order, the standard for steel was categorised with IS 1786 Grade 500. This is a particular order from a specific company. We are not accustomed to producing a purchase order with so many details. Whenever a purchase is made from a seller, we only provide certain minimum specifications. IS, BS, ASTM and BDS are all co-related standards. The issue with the purchase order was that it did not include the equivalencies, which paved the way for more confusion. What we must assess are the specifications of Bangladesh Railway.

I believe that since international contractors are used, all standards should be included within a project so that a mixture of them may be at our disposal. The buyer then makes purchases according to its company policy.

The cost of building materials alone constitutes 65 to 70 percent of the total cost of any construction project in Bangladesh. We are lucky to have locally processed construction materials, in particular, cement and steel. However, the raw materials are imported.

In terms of concrete production, the gradation of the coarse and fine aggregates is very important. However, since material proportions are fixed, we do not opt for mixed designs. If design, gradation and fixing of cement content are done on a case-to-case basis, with respect to the materials available in the market, materials can be saved. Current fixed material proportions can be excessive for particular grades of cement. Even though we already choose mixed designs for larger projects, this should also be applied to smaller projects.

Most companies send their material samples to BUET for quality control testing, thereby overburdening them. People hold the misconception that only BUET can adequately perform testing. Standard testing laboratories should be established across the country by either the government or the private sector. A legal framework for the supervision of private construction projects is required as well. There are government schemes for the up-skilling of individuals involved in supervision. However, this scheme is insufficient and must be expanded. Awareness of owners regarding the use of locally processed construction materials over imported products is also crucial.

A F M Saiful Amin

Professor, Department of Civil Engineering, BUET

Standards are the products of knowledge-based assessments. They are the outcomes of long-term evaluations. Bangladesh's research base is not as strong as it should be. The Bangladesh National Building Code (BNBC) was written using the American standard. When it came to the materials, BDS standards were used, which include IS standards as well. All these standards comply with each other despite some mismatches. Within the BNBC, there have not been many conflicts amongst the varying standards.

Indian standards have been followed (Indian Rail Code (IRC)) in our country for the installation of rail systems. Unfortunately, there still isn't a separate rail code for Bangladesh. Our major bridge projects also do not have local codes which may be followed. We must start by evaluating designs. Designers follow the codes which have been given, and so, we need our own national codes for our railway sector and our bridges. We must find custodians for our rail system and bridges as well.

When it comes to education, we are following the American system. It does not mean that European standards are inferior, as all standards are based on research and knowledge. As for legal matters, each nation has certain rules and regulations which must be followed.

What is most important, and also challenging, is the implementation of laws at field levels. Material has a physical existence. The same material can satisfy different testing standards. Therefore, in terms of compliance issues, we need to see things from a larger perspective. If we look at the total material consumption in our mega projects, our national industry is at a grooming stage. We have to import big chunks of our steel sections. Thus, we should promote our local industry in this regard, and their standards will also qualify in all instances. We should see to what extent they comply because if they comply, they can be used. We can then obtain inclusive compliance. We must also focus more on industrialisation, especially as we undertake more mega projects.

Engr F R Khan

Managing Director, bti (Building Technology & Ideas Ltd)

In construction, there is a standard deviation of five to ten percent, and many differ up to 15 percent in some cases. Bangladesh National Building Code (BNBC) 2015 still has not been approved, and we are using BNBC 1993, which is almost 30 years old. Therefore, sometimes we have to mention alternative building codes. We had been using ACI up until BNBC had been introduced. BNBC took 15 years to be approved. We are still awaiting approval for the new terms of BNBC.

Building code standard starts with the design. If we follow through with the proper protocols, the safety of the structure, the people, and the workers can all be maintained. After the design is done, it can be rechecked by the proper bodies through an internal or external audit.

After the design, we move on to the construction, which can be divided into three categories. The structural system is the most important aspect of construction, and the design needs to be adequately reflected through it. The integrity of this structural system, in bti, is ensured through the ISO 9001-2008 certification. The developers or buyers can employ other external or internal audits as well. Next, we need to look into the sustainability of the building. The structure needs to be architecturally functional for the upcoming generation. The building standard code needs to start incorporating this sustainability factor. The third part of the construction is the electromechanical system, which is essential for ensuring the building's longevity. The electrical lines, mechanical lines, and plumbing of the buildings must strictly follow the BNBC standards. After following through with all these building standards, without proper maintenance, long-term sustainability and safety cannot be ensured.

A century ago, there were no building standards, and yet we have buildings standing tall from that era. The reason for that is the consistency of the materials used in their constructions.

For the post-COVID era, we should look into integrating health and wellness centres and children's playing areas into the building designs.

Md Abu Sadeque

PEng., Executive Director, HBRC

There are no standards present in regards to the longevity of a building. Apart from rods and steel, we also need to create building standards for the bricks, partition wall, plumbing and electric system, etc., used in construction.

Safe construction is equated with sustainable construction. Building construction should be aimed towards the future generation and should not be at their expense. If we consider sustainability, the end product of every material and structure should have a sustainable standard.

We should not hesitate to use the international standard cement and steel for our construction projects since we do not have a standard rail code or bridge code.

The unfortunate scenario is that our own government does not honour the national standards during building a structure.

According to a study conducted by HBRC, out of all buildings constructed in Bangladesh between 2020 and 2030, 80 percent of total energy will be consumed by embodied energy and only 20 percent by operating energy. This means the construction materials used for the buildings will require 80 percent of total energy. If we want to adopt green or sustainable construction, the percentage of embodied energy must be reduced.

BSTI's efficiency must be increased. If we are adopting an international standard, this standard must be customised. Unfortunately, BSTI does not have the capacity to carry out this customisation. Therefore, capacity building in BSTI is required.

BSTI controls the standard, whereas Housing and Building Research Institute (HBRI) conducts research and develops building codes. The organisations are not working in harmony.

There should be a separate board and standards for rural housing. A code of practice must be formulated to implement building codes.

Dr Md Shamsul Hoque

Professor, Department of Civil Engineering, BUET& Director, Bureau of Research, Testing and Consultation (BRTC)

Our current materials industry is world-class. Their production uniformity and consistency has reached excellent heights. In regards to raw materials for sustainable development, Bangladesh is currently self-sufficient.

Since the compliance and output level of the production houses related to our construction industries are now of international quality, we can try and discourage the import of such materials from other countries. This will further help better our own industries as well.

Another aspect we must look into is the proper mixing of all the ingredients for the preparation of the materials. Without proper mixing, we cannot expect to progress towards safe and durable development. Site supervision is necessary to rectify this. Even when we have all the standard materials, we must also ensure that no compromises are being made during the actual construction. I urge the construction industries to build up a standard for the supervision of the construction sites.

Prof Dr M Shamim Z Bosunia

Chairman and Managing Director, Abode of Consultants (Pvt) Ltd and Former President, Institution of Engineers, Bangladesh

The "Padma Bridge Rail Link Project" is supervised by the Bangladesh Army. Is there any technical committee which is associated with the project? The Padma Bridge project has a panel of experts. Bangabandhu Sheikh Mujibur Rahman Tunnel (or Karnaphuli Tunnel) also has such a committee. Therefore, the railway project should have a technical committee as well.

Construction quality is not solely dependent on the standards of construction materials; it can be maintained if workers are adequately trained, ethics are upheld, and the engineers supervise correctly. Cement companies in Bangladesh now maintain high standards. The current production capacity of different companies is over 70 million tonnes, yet the demand is only around 35 to 40 million tonnes. Consequently, companies will not be able to produce cement of lower quality. Bangladesh is not self-sufficient in steel production. Still, a good number of companies are trying to produce high-quality steel.

Many cement or rod companies state that their materials are tested and approved by BUET. However, BUET does not hold the authority for this. BSTI is the only authoritative body that tests the standards of all construction materials in Bangladesh. Therefore, BSTI should be strengthened.

The most important part of constructing a building over ten-storey high are the columns at the end of the beam. Every joint should be photographed and sent to the designers.

Due to the COVID-19 pandemic, construction work was halted for a while. After the pause, cracks in the concrete and rusting on the rods were found on the structures. Issues during the casting of the concrete may have caused these cracks.

Institution of Engineers, Bangladesh (IEB) has a registration board that provides certifications on who is permitted to design or supervise. This certification needs to be implemented more strongly.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments